Project Overview

The ALQ80 asphalt mixing plant consistently achieved its designed output of 80 tons/hour, providing excellent asphalt mixture quality that fully met the high standards of highway construction, laying a solid foundation for the overall project quality.

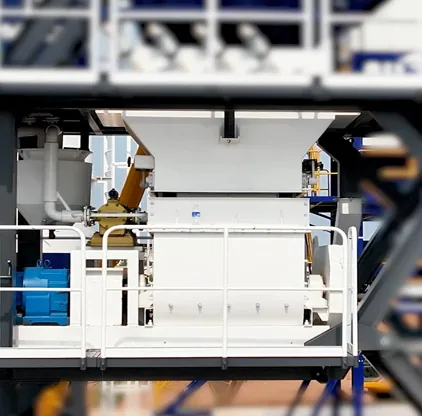

Product:ALQ80 Asphalt Batching Plant

Application:Asphalt supply for local road construction

ConfigurationVibrating screen 4 Layer, 40 m³ asphalt storage tank

Location:in Mongolia

80TPH ALQ80 Asphalt Batching Plant for

Road Construction in Mongolia

Customer Background

The client is a large local infrastructure contractor with no prior experience operating asphalt equipment. They are currently undertaking a significant regional highway upgrade project and require a reliable and moderately efficient (80 tons/hour) plant.

Challenges Faced by Client

Limitations of Traditional Plants:

Ensure a stable supply of asphalt materials.

High-Quality Asphalt Production:

Ensure the project can overcome extreme environmental challenges;

Complex Installation:

Achieve rapid deployment and sustained, stable production;

Why Choose 80TPH Asphalt Mixing Plant?

The ALQ80 asphalt mixing plant features a highly integrated and modular structure. All major components (such as the mixing plant and aggregate conveying system) are designed as easily transportable and quickly assembled units, significantly shortening the on-site installation period and perfectly meeting the customer’s demand for rapid commissioning.

80TPH Production Capacity

Meets high-volume demand for road construction

Modular Mobility

Modular and Rapid Deployment Design

High-Capacity Thermal Energy Storage System

Equipped with one independent 40 m³ asphalt storage tank

Positive Client Feedback

Thanks to Macroad’s professional team of on-site engineers and the equipment’s modular design, the ALQ80 was successfully installed and commissioned. The plant was quickly operational within a very short construction window, ensuring the on-time start of the highway paving project.