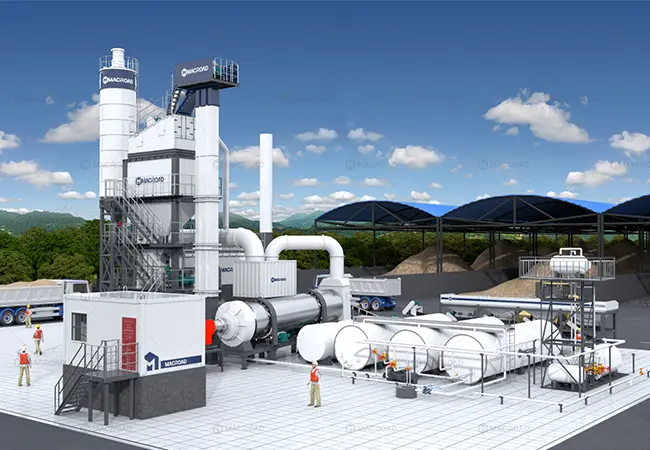

From Highways to Urban Roads: One Plant, Every Solution.;

Get Quote Online Now

Types of Asphalt Mixing Plants

Asphalt mixing plants, or asphalt plants, combine components to produce asphalt. we offers batch & drum type plants to meet the needs of large, medium and small asphalt road construction projects. The following are different asphalt mixing plant types for you to choose.

ALQ Asphalt Batching Plant

Hot Models:80t/h120t/h160t/h200t/h

Productivity: 80t/h-400 t/h

Features:

1. High-precision weighing system: meeting high quality requirements for asphalt;

2. Larger mixers ensure efficient production, up to 400t/h;

Application:

Highway mainline construction, airport runway engineering, high-precision grading and ultra-large capacity demand projects;

Get A Quote

ALYQ Mobile Asphalt Batching Plant

Hot Models:80t/h100t/h120t/h

Productivity: 60t/h-160 t/h

Features:

1. High-precision weighing system: meeting high quality requirements for asphalt;

2. Equipped with mobile device, easy to move and transfer;

Application:

Provincial/national highway construction, and expansion, urban road construction and other multi-section transfers and medium capacity demand;

Get A Quote

ALT Asphalt Drum Mix Plant

Hot Models:40t/h60t/h80t/h120t/h

Productivity: 40t/h-160 t/h

Features:

1. Small footprint, compact structure, continuous drum mixing;

2. Quick return on investment and reduced project costs;

Application:

Urban road construction, port logistics channel road paving and other long-term stable production projects;

Get A Quote

ALYT Mobile Asphalt Drum Mix Plant

Hot Models:40t/h60t/h80t/h120t/h

Productivity: 40t/h-160 t/h

Features:

1. Drum design, continuous drum mixing;

2. Installing mobile devices, easy transportation and rapid deployment;

3. No need to worry about moving, the construction period will not be delayed;

Application:

Urban roads, rural roads and other scattered sections and short-term demand projects;

Get A Quote

The Production and Usage of Asphalt Mixing Plants

| Usage | Main Benefit/Advantage | Typical Application Scenarios |

|---|---|---|

| 1. Construction Engineering | Provides core material, ensuring quality of pavement construction | New construction of expressways, urban road resurfacing, airport runways |

| 2. Cost Control | Eliminates intermediary markups, reducing overall project cost | Supplying own projects, achieving vertical integration |

| 3. Commercial Profit | External sales of hot mix asphalt (HMA), generating revenue | Regions with concentrated engineering projects, supplying to competitors |

| 4. Schedule Guarantee | Controllable material supply time, independent of external limitations | Time-sensitive projects, emergency road repairs |

| 5. Environmental Compliance | Utilizes advanced equipment to meet environmental standards | Urban industrial areas, projects with strict environmental requirements |

Intelligent Modular Technology: Intelligent Production Efficiency Increased by 30%

Are you still worried about the high energy consumption and frequent failures at your asphalt plant? We understand the challenges you face in project operations: traditional equipment has a high failure rate, frequent maintenance downtime hinders project progress, and the risk of huge compensation can be overwhelming. With years of experience in asphalt machinery manufacturing, we offer you more than just a set of equipment; we offer a complete road construction solution featuring intelligent modular technology.

Real – time Monitoring

- Saving the maintenance cost by 25%, and extending the equipment life by more than 15%. When an abnormal state occurs, it can automatically alarm and generate a diagnostic report

Predictive Maintenance

- Based on the operation time and component wear data, the IOT can intelligently push the maintenance plan, reducing the risk of sudden failure shutdown.

Remote Control:

- Integrated intelligent control system can simplify 50 operations into one – key control, improving production efficiency.

Global Projects

Asphalt mixing plants have become increasingly popular worldwide due to their efficiency, reliability, and versatility. These plants have been exported to various countries, for example: Jamaica, Papua New Guinea, Bosnia and Herzegovina, Mongolia, Malaysia, Indonesia, the Philippines, Kazakhstan, Uzbekistan, Democratic Republic of the Congo, etc.

80TPH ALQ80 Asphalt Batching Plant for Road Construction in Mongolia

Country: in Mongolia

Model: ALQ80 asphalt batching plant, Capacity: 80 tph

Challenge: High-quality asphalt production, ensure the project can overcome extreme environmental challenges;

Achievement:

1. A high-efficiency and high-precision heating system is used to ensure production quality.

2. At the same time, real-time monitoring is carried out through the IoT intelligent system: key parameters such as aggregate heating temperature, asphalt metering, and finished mixture factory temperature are monitored and recorded in real time.

Customer Testimonial: The plant was quickly operational within a very short construction window, ensuring the on-time start of the highway paving project.

Get A Quote

ALQ80 Asphalt Mixing Plant Has Shipped to Philippines

Country: Philippines

Model: Model ALQ80, Capacity: 80 tph

Challenge: To ensure expedited production, engineers needed to be dispatched for installation and any issues needed to be addressed promptly.

Achievement: The client completed the large-scale asphalt paving project in a short period of time. This significantly shortened the project schedule, minimized disruption to local traffic, and improved overall efficiency.

Customer Testimonial: I am very grateful that they sent engineers to install the asphalt mixing plant. The plant is easy to operate and the technicians can quickly operate and produce independently.

Get A Quote

Bosnia and Herzegovina Road Construction Project: Using an ALYT80 Asphalt Plant Reduced Construction Time by 15%.

Country: Bosnia and Herzegovina

Model: Macroroad ALYT80, Capacity: 80 tph

Challenge: 200 consecutive days of high-intensity operation, requiring extremely high equipment reliability.

Achievement: The equipment achieved a mean trouble-free uptime of over 500 hours, ensuring stable nighttime rush work and helping the client achieve delivery 15% ahead of schedule.

Customer Testimonial:” Equipment’s stability exceeded our expectations, truly giving us peace of mind and peace of mind.”

Get A Quote

Applications of the Asphalt Batch Mix Plant

Asphalt batch mixing plants are core equipment for large-scale infrastructure projects, high-grade road construction and regional material strategic reserves. They are irreplaceable in the construction of highways, hub airports, port heavy-load roads, etc.

Highway

Heavy Traffic Road

Airport Runway

City Expressway

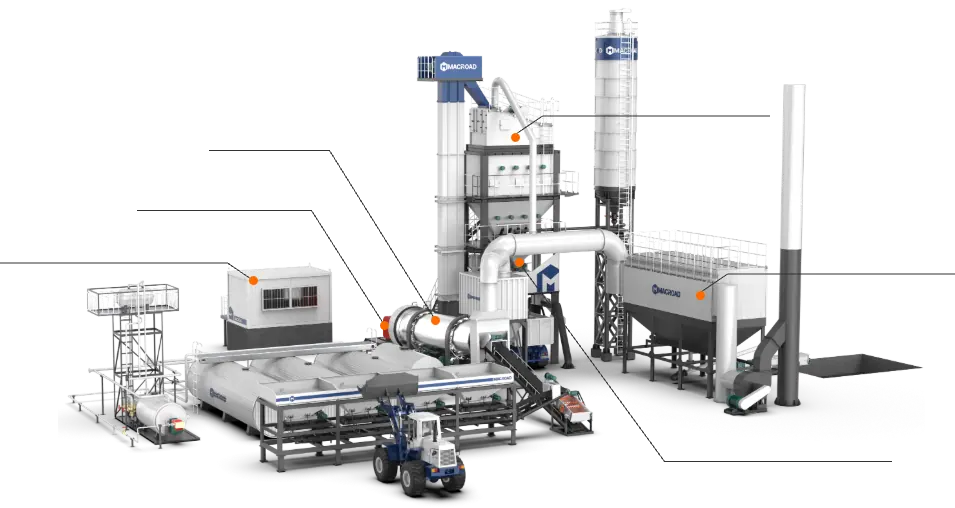

Main Sysem of the Asphalt Mixing Plant

The performance of an asphalt mixing plant hinges on the seamless integration of its core components, each playing a vital role in ensuring productivity and high-quality output. Key components include:

Drying Drum

Burner System

Control System

Vibrating Screen

Dust Filter

Mixing Unit

Aggregate Batching System

- Main includes: batch hopper, feeding belt, collecting belt, vibrating screen and belt conveyor.

- The hopper capacity is upgraded to 9m³*4, and the belt conveyor is equipped with a pull-rope switch emergency stop device.

Drying System

- Consists of drying cylinders, combustion devices, and oil ignition system components.

- Various fuel options (oil, fine coal, natural gas) to save operating costs.

Screening System

- Screen area increased by 30%, improving work efficiency.

Dust Collecting System

- Two collecting levels: cyclone dust filter and bag dust filter.

- Compared with gravity dust removal, cyclone dust removal has better dust removal effect, reduces the load of bag dust collector, and prolongs its life.

Bitumen Supply System

- Composed of bitumen tank, bitumen gear pump, pipes, and bitumen spray tube.

- The default fuel for the burner of the thermal oil furnace is diesel, with optional coal and natural gas.

Electrical Control System

- Adopts centralized control technology, composed of distribution cabinets, control room, and other small auxiliaries.

- Four operation modes: control cabinet button/touch screen, computer, mobile phone APP.

Our Service

The performance of an asphalt mixing plant hinges on the seamless integration of its core components, each playing a vital role in ensuring productivity and high-quality output. Key components include:

Customized Design Plans

If you are new to the asphalt mixing plant, or need customized plans for your project, we can help you to find the most suitable plan for you. we are aimed to provide solution with reasonable price and perfect service.

Factory Inspecting Test

Before transportation we will has strict machine inspection to ensure product quality, such as, material supervision, welding inspection, coating inspection, packing inspection, loading inspection, etc.

Spare Parts Exchange & Maintenance Service

Providing 12 months warranty. After that we also provide regular maintenance service to you. We will provide you necessary parts and training operator how to exchange them. If we have overseas branches nearby, we will sent our resident engineer to have regular revisit.

Installation & Commissioning Service

As soon as the machine was shipped to destination, our after-sales engineer will fly to local work-site to help installation, running test and operation training service.

Related Products for Road Construction

As a trusted supplier of asphalt plants, we also provide a complete range of road building equipment to meet all your project needs. Whether you focus on asphalt production, paving, or subgrade stabilization, we offer the support to keep your operations running smoothly.

Modified Bitumen Plant

Asphalt Paver

Stabilized Soil Mixing Plant