Intelligent production efficiency increased by 30%;

The max capacity: 400 t/h, flexible to choose;

Latest Projects

Build Better Roads: How ALQ80 Meets Strict Highway Standards & Saves Labor Costs”

- Customer Needs:

Need an efficient and reliable asphalt mixing plant for highway and urban road construction. - Challenges Faced:

1. Highways require extremely precise asphalt mix quality with minimal tolerances.

2. Urban roads need to minimize manual operations and labor costs. - Solution: ALQ8O 80t/h Asphalt Mixing plant

1. High-precision weighing: Aggregate tolerance ±0.5%, asphalt ±0.25% for highway-grade quality.

2. Full automation: Automated control from batching to discharge, reducing labor needs. - Results & Value Delivered:

1. 30% higher production efficiency with fast commissioning.

2. Consistent, high-quality mix meeting all standards.

3. Simple operation with significant labor savings.

Get A Quote

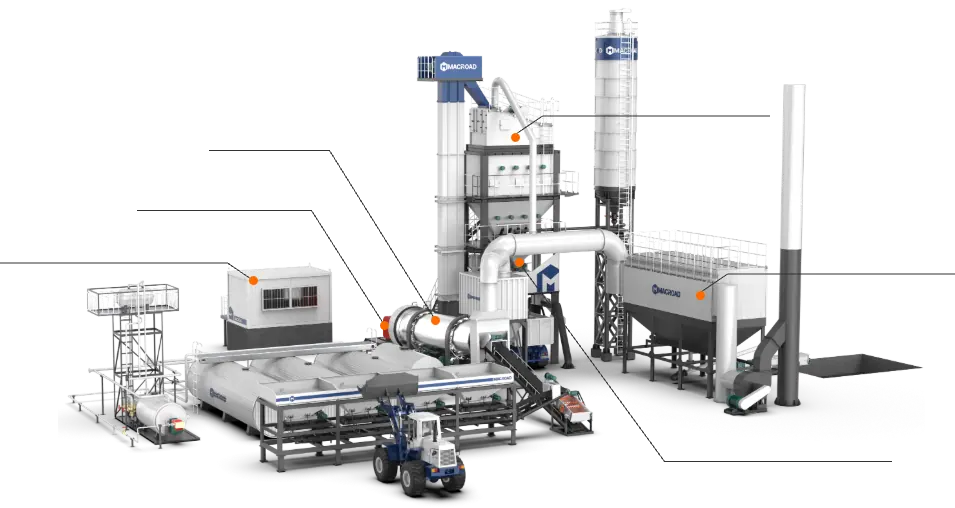

Types of Our Asphalt Mixing Plants

ALQ Stationary Asphalt Batch Mixing Plant

Hot Models:80t/h120t/h160t/h200t/h

Productivity: 80t/h-400 t/h

Application: highway mainline construction, airport runway engineering, large-scale infrastructure in urban core areas and other high-precision grading and ultra-large capacity demand projects;

Get A Quote

ALYQ Mobile Asphalt Batch Plant

Hot Models:80t/h100t/h120t/h

Productivity: 60t/h-160 t/h

Application: Provincial/national highway construction, and expansion, urban road construction and other multi-section transfers and medium capacity demand;

Get A Quote

ALT Drum Asphalt Plant

Hot Models:40t/h60t/h80t/h120t/h

Productivity: 40t/h-160 t/h

Application: urban road construction, port logistics channel road paving and other long-term stable production projects;

Get A Quote

ALYT Mobile Drum Asphalt Plant

Hot Models:40t/h60t/h80t/h120t/h

Productivity: 40t/h-160 t/h

Application: urban roads, rural roads and other scattered sections and short-term demand projects;

Get A Quote

IoT Upgrade, Production Efficiency Increased by 30%!

- 1. Real-Time Monitoring, Full Visibility → Save Time & Boost Efficiency

24/7 remote monitoring of equipment status and production data eliminates frequent manual checks, reducing on-site management time by 30%, enabling faster, smarter decisions anytime, anywhere. - 2. Smart Alerts, Proactive Prevention → Save Costs & Reduce Downtime

Automated maintenance reminders prompt timely part replacements, preventing unplanned breakdowns and production halts, cutting emergency repair costs by 50% and extending equipment lifespan by 20%. - 3. Data-Driven Optimization → Reduce Labor & Increase Output

AI-powered performance analysis auto-adjusts machine settings, minimizing manual tuning while boosting productivity by 15%, all with less operator effort.

Global Projects

We are always a trusted partner in the industry! We have been deeply involved in the field of asphalt mixtures for many years and have provided precise and adaptive solutions for hundreds of road projects around the world; currently including highways, municipal trunk roads, airport runways, port yards and other special scenarios.

ALQ160 Asphalt Mixing Plant Enhances Road Construction Efficiency in Kazakhstan

1. Customer Needs

High-capacity production ≥1,500 tons/day

2. Challenges

Capacity gap: The actual production capacity (traditional type) is lower than the theoretical demand of 160 tons/h

3. Solutions

✓ Speed optimization: Daily paving mileage increased to 42 km/day (industry average: 28 km)

4. Results

The ALQ160 reduced production time by 37.5%, allowing the project to finish weeks ahead of schedule

ALQ100 Asphalt Mixing Plant Deploys to Indonesia for Cost-Efficient Road Infrastructure

1. Clients Need

Reduce asphalt procurement costs by 30% through in-house production

2. Challenges

Cost volatility: 65% of asphalt materials previously imported with price fluctuations

3. Solutions

Automated quality control: sensors for real-time additive monitoring (±0.2% tolerance)

4. Outcomes

Sustainability impact: Reduced logistics cost by 50% via localized production

Upgrades of the Main Components

The performance of an asphalt mixing plant hinges on the seamless integration of its core components, each playing a vital role in ensuring productivity and high-quality output. Key components include:

Drying Drum

Burner System

Control System

Vibrating Screen

Dust Filter

Mixing Unit

Drying Drum

- Efficient aggregate drying with precise temperature control

- Double-layer insulated discharge pipe ensures 100% temperature compliance

Burner System

- Provides stable heat and optimized fuel efficiency for the drying and heating process.

- Heating system is optional:coal, diesel, natural gas.

Vibrating Screen

- Enhanced screening accuracy;

- 30% larger area + quick-release screen structure

Mixing Unit

- 4/5-bin cold hoppers (20% larger single-bin capacity)

- Separate storage & weighing system (aggregate ±1%, powder/additive ±0.5%) Ensures uniform mixing for durable asphalt mixtures

Dust Filter

- Two-stage dust removal (Cyclone + Bag filter), upgraded recycling

- Cyclone collects reusable sand; Bag filter ensures thorough purification

Control System

- Triple control modes (touch screen/PC/buttons)

- Automated operation guarantees precision & productivity

Applications of Asphalt Paving

The application of macroad asphalt mixing plant currently covers road construction, maintenance, recycling. With the advancement of technology, its application scope is also developing towards environmental protection (recycled asphalt), intelligence (warm mix technology) and multi-functionality (permeable/colored asphalt). Different scenarios require adjustment of asphalt ratio, additives and production processes to meet the balance between performance and cost. At present, the application areas we cover are:

Highway

Heavy Traffic Road

Airport Runway

City Expressway

Our Service

The performance of an asphalt mixing plant hinges on the seamless integration of its core components, each playing a vital role in ensuring productivity and high-quality output. Key components include:

Customized Design Plans

If you are new to the asphalt mixing plant, or need customized plans for your project, we can help you to find the most suitable plan for you. we are aimed to provide solution with reasonable price and perfect service.

Factory Inspecting Test

Before transportation we will has strict machine inspection to ensure product quality, such as, material supervision, welding inspection, coating inspection, packing inspection, loading inspection, etc.

Spare Parts Exchange & Maintenance Service

Providing 12 months warranty. After that we also provide regular maintenance service to you. We will provide you necessary parts and training operator how to exchange them. If we have overseas branches nearby, we will sent our resident engineer to have regular revisit.

Installation & Commissioning Service

As soon as the machine was shipped to destination, our after-sales engineer will fly to local work-site to help installation, running test and operation training service.

Related Products for Road Construction

As a trusted supplier of asphalt plants, we also provide a complete range of road building equipment to meet all your project needs. Whether you focus on asphalt production, paving, or subgrade stabilization, we offer the support to keep your operations running smoothly.

Modified Bitumen Plant

Asphalt Paver

Stabilized Soil Mixing Plant