Project Overview

The client is a road construction and paving contractor based in Subang, Indonesia. Historically, their business model relied on procuring finished asphalt mix from external suppliers for their road projects. In the long run, the increasing prominence of cost fluctuations and quality stability issues, especially when dealing with large-scale, high-standard projects such as highways, presents greater challenges.Their decision to purchase an asphalt mixing plant marked a strategic pivot towards achieving self-sufficiency and greater operational control.

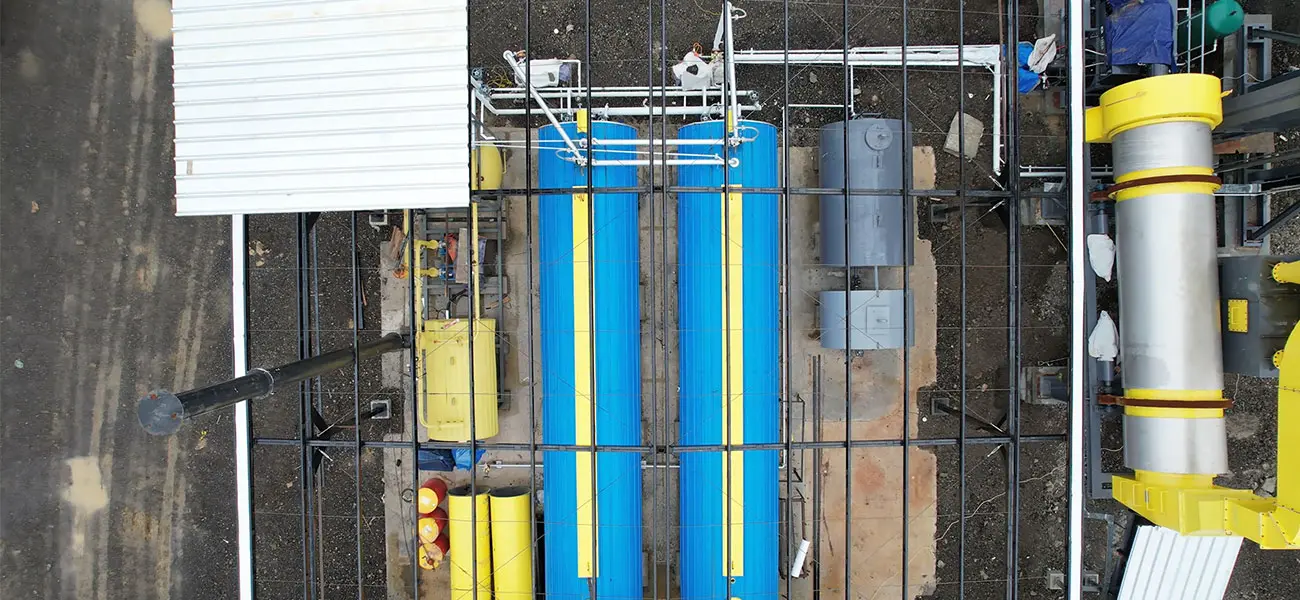

Product:ALQ100 Asphalt Mixing Plant

Application:Various Road Construction Projects

ConfigurationEquipped with a finished bin to ensure uninterrupted production.

Location:in Subang, Indonesia

Challenges Faced by Client

Reliance on external suppliers for the finished mix means clients are exposed to volatile market pricing, which directly undermines the profitability of their projects. Given that their contracts typically cover high-specification work, such as highway construction, these projects have a critical requirement for asphalt mixtures of superior and consistent quality.

1. Controlling Raw Material Costs (Long-term Strategy)

From a long-term strategic perspective, the client needed a solution that would allow them to manage and significantly reduce raw material procurement costs by buying aggregates and bitumen separately and handling the mixing in-house.

2. Ensuring High-Quality Asphalt Mix Production

They required a solution that could guarantee the precise proportions and thorough mixing necessary to meet the stringent quality specifications required by the Indonesian Department of Highways.

3. Improve Production Efficiency

This ensures sufficient daily asphalt production, preventing production delays due to insufficient purchased raw materials.

Our Solution: ALQ100 Asphalt Batch Mixing Plant (100 T/H)

We provided the high-efficiency ALQ100 Asphalt Batch Mixing Plant with a capacity of 100 tons per hour, tailored to meet the client’s exact quality and volume requirements. Key features addressing the client’s challenges include:

1. Twin-shaft concrete mixer:

Designed to thoroughly mix all materials. This ensures uniform dispersion of various aggregates, mineral fillers, and asphalt, thereby guaranteeing a high degree of homogeneity and superior quality of the final asphalt mixture.

2. High-precision weighing system:

Meets the stringent quality standards of highway projects. Aggregate weighing accuracy: ±0.5%, Asphalt weighing accuracy: ±0.25%

3. Fully automated and remote IoT monitoring:

Real-time monitoring of the production process from a remote location. Receives automatic maintenance alerts, optimizes uptime, and reduces the need for continuous on-site supervision, thereby significantly reducing labor costs.

From Every Core Component to Overall Reliability

A high-performance asphalt mixing plant is the cornerstone of success for highway and infrastructure projects. Our secret to ensuring superior performance and enduring reliability in every asphalt plant lies in the rigorous quality control and meticulous manufacturing of every critical component:

Value Delivered to the Client

Increased Production Efficiency: The plant achieved a 30% improvement in production efficiency shortly after its rapid installation and commissioning, ensuring projects are completed on schedule